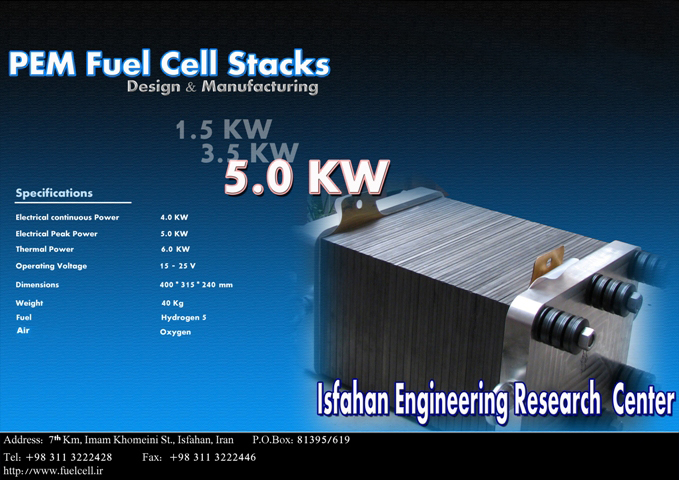

Proton Exchange Membrane (PEM) is well known among other types of the fuel cells. In theses types of fuel cells, the electrolyte is a polymer and they operate at temperature of about 80 oC with high efficiency. PEM fuel cell is a chosen to be the viable fuel cell for a wide range of applications, from low-Watt (e.g., cellular phones, lap-top computers) to high-Watt (e.g., stationary power plants). A unit-cell can produce about 0.6-07 Volts and is considered to be the building block of a fuel cell stack.

The current obtained by a fuel cell depends on the area of each cell and the quality of the materials used and their assembly. Each unit cell consists of different subsections, like MEA (Membrane-Electrode-Assembly), bipolar plates, seals, and catalyst. MEA by itself has three subsections: like membrane, catalyst and gas-diffusion-layers).

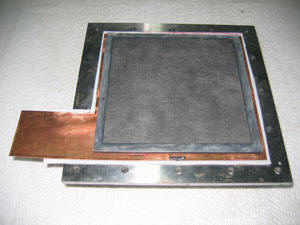

MEA: is a major part of the PEM and is considered as the heart of the cell. All chemical and electro-chemical reactions happen in MEA. A polymeric membrane with layers of catalyst (usually Pt) is sandwiched by two carbon papers or GDL (Gas-Diffusion-Layer). A GDL is a porous carbon paper and its function is to feed the active gases to the catalyst layer and transport the bi-product (mainly water) to the outside of the cell.

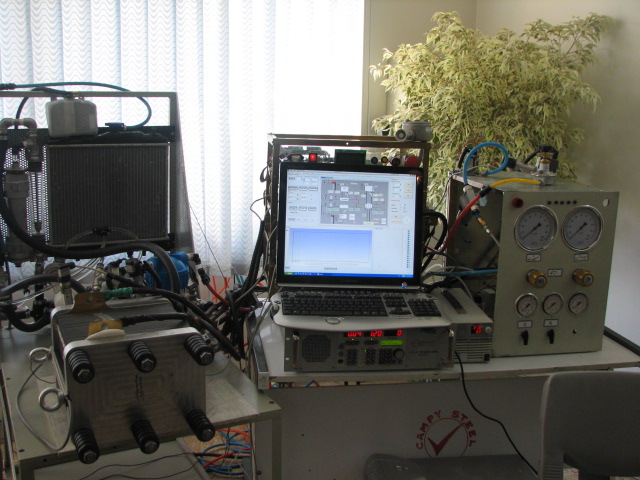

The H2 gas is supplied to the anode side of the MEA and the O2 (or air) to the cathode side. Hydrogen is then electrochemically decomposed to electrons and protons. The membrane is conductive to protons and prevents electrons to pass through. Hence the electrons (i.e., electricity) go around and reacts electrochemically with Oxygen on the cathode side to produce water.

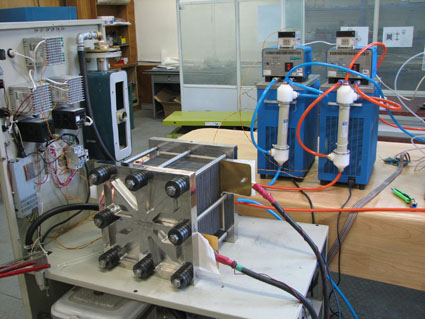

The development of MEA is a complex one and needs establishing several processes in the laboratory. At IERC, we have developed MEA with active areas from 3x3 cm2 to 14x14 cm2. Test results for these MEA�s are satisfactory and further improvements are optimizations are scheduled.

End-plates and seals: In order to seal the leakage of the gases and the liquid water as well as preventing electrical shorts between unit-cells in a stack, we need to develop seals that are resistive and durable enough in the cell environment. We are also working on developing the end plates, which should conduct the current, & voltage produces by the stack.

Tel:+98311-3222428

Fax:+98311-3222446

E-mail: info@fuelcell.ir